SAINA® Synthetic Paper

Durable synthetic paper that offers easy, high-quality printability, strong adhesion and tamper-evident security

Ruggedly Durable

Resists water, chemicals, abrasion, tearing and extreme temperatures for durability and exceptional strength

Amazingly Printable

Prints as easily as paper, unlike other synthetic substrates,does not melt in laser printers

Inherently Secure

Tamper-resistant material locks in laminates, inks and toners to secure print information

Ruggedly Durable

SAINA ® substrate combines the strength and dimensional stability of polyolefin with the absorbency of silica to form a unique microporous matrix. The result is a range of durability benefits not available from competing synthetic paper stocks, including:

Abrasion- and scuff-resistance – Printed text and graphics cannot be scratched or rubbed off the surface of Saina substrate without destroying the material itself. This print permanence results in tamper-evident/tamper-resistant performance without the need for laminates or protective coatings.

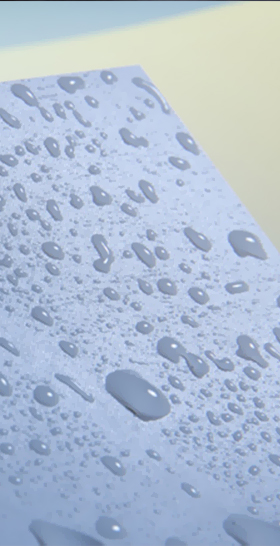

Water-resistance – Polyolefin is hydrophobic, which causes Saina substrate to repel water.

Chemical-resistance – Saina substrate withstands exposure to a variety of chemicals and solvents and can even be dry-cleaned. Most other synthetic papers require a coating to perform as well as Saina substrate does without enhancement.

Thermal stability – Saina substrate remains pliable in temperatures from -70°C/-94°F to 180°C/356°F, even during prolonged exposure or rapid temperature change. Unlike Saina substrate, other synthetics can become brittle or melt when exposed to elevated temperatures such as those generated by desktop laser printers.

Tear-resistance and conformability – The flexibility of Saina substrate enables it to resist tearing and to conform to pointed, rough and uneven surfaces or fluid-filled bags.

Ink and toner protection – Inks and toners absorb into Saina substrate’s microporous matrix, locking printed text and graphics into its surface and making them nearly indestructible.

Lamination- and finish-friendly – Saina substrate bonds with laminate films when either the adhesive or the laminate itself flows into its pores, enhancing the durability of the material. Due to the unyielding strength of the resulting mechanical bond, edge-sealing isn’t required and Teslin substrate is able to withstand punishing finish processes such as perforating, punching, folding, sewing, grommeting, foil stamping and embossing without cracking.

Amazingly Printable

Thanks to its highly absorptive, microporous structure, SAINA® substrate prints like pulp paper while providing all the performance benefits of a synthetic, making it ideal for print applications that demand high levels of processing flexibility, together with exceptional color, graphic and print reproduction. Compare the performance advantages of Saina substrate and see why it is like no other synthetic paper stock:

Compatible with multiple print technologies – No other printable plastic accommodates as broad a range of print technologies as Saina substrate. Compatible technologies include offset, flexographic and digital platforms such as laser/electrographic, inkjet and thermal transfer printing. It also functions well with gravure, screen, intaglio, split fountain, micro-printing and more.

Requires no special inks or drying equipment – The print characteristics for Saina substrate are similar to conventional paper, so it does not require special oxidizing inks or drying equipment, as many synthetics do.

Dries quickly for easy processing and fast throughput – Inks and toners absorb into Saina substrate and bond to its microporous structure remarkably fast. In addition to providing brilliant color reproduction and virtually indestructible text and graphics, this permits inks and toners to dry almost instantaneously for quicker processing and throughput than other synthetics.

Can be duplex and dual-surface printed – Saina substrate is perfect for variable printing applications because it doesn’t need a special coating or treatment to be duplex- or dual-surface printed with high-quality graphics.

Accommodates a variety of converting methods and finishing techniques – Saina substrate maintains strength and flexibility during finishing processes such as perforating, punching, folding, sewing, grommeting, foil stamping and embossing.

Inherently Secure

The microporous matrix of SAINA® substrate, combined with its unique performance characteristics, provides built-in security features that protect and help ensure the integrity of secure credentials and documents, e-Passports, labels and other applications. They include:

“Locked-in” data for secure protection – Saina substrate absorbs ink and toners and locks them into its surface almost instantaneously. Printed text, bar codes, graphics and other critical data cannot be scratched off without damaging the material itself. Other synthetics rely on coatings to adhere inks and toners to their smooth surfaces. Saina substrate does so without laminates and protective coatings, which enables it to be tamper-resistant and tamper-evident without additional enhancement.

High-definition print for color imaging – Saina substrate accommodates precision printing of text, bar codes, QR codes, microprint text, color photos and other security data more effectively than other synthetic substrates that only allow inks and toners to rest on their surfaces. Saina substrate is also compatible with a wide range of security print technologies, including offset, digital and laser printing.

Customizable for authenticable security applications –Saina substrate can be formulated with security features during manufacture and delivered through an exclusive, secure supply chain. This Saina Security-Grade product can also be made program-specific to enhance traceability to and authentication by individual security program operators and/or organizations. The visual effects that result from incorporating program-specific security features into the structure of Saina substrate can make it easier to identify credentials counterfeited through printing, coating or other post-manufacturing methods.

Difficult to replicate – While the Saina substrate performance features listed above make credentials more difficult to counterfeit, there are two additional ways to enhance their security. The first is to layer secure documents with Saina substrate in combination with other substrate materials such as polycarbonate (PC), polyvinyl chloride (PVC) and glycol-modified polyethylene terephthalate (PET-G). The other is to produce credentials using Saina Security-Grade substrate embedded with customized security markers that can only be traced to and authenticated by the credentialing organization to which it was sold. When combined, these two strategies deter counterfeiters by demanding significant investments in capital, time and skill, and by incorporating substrate materials that are not readily available to them on the open marketplace.